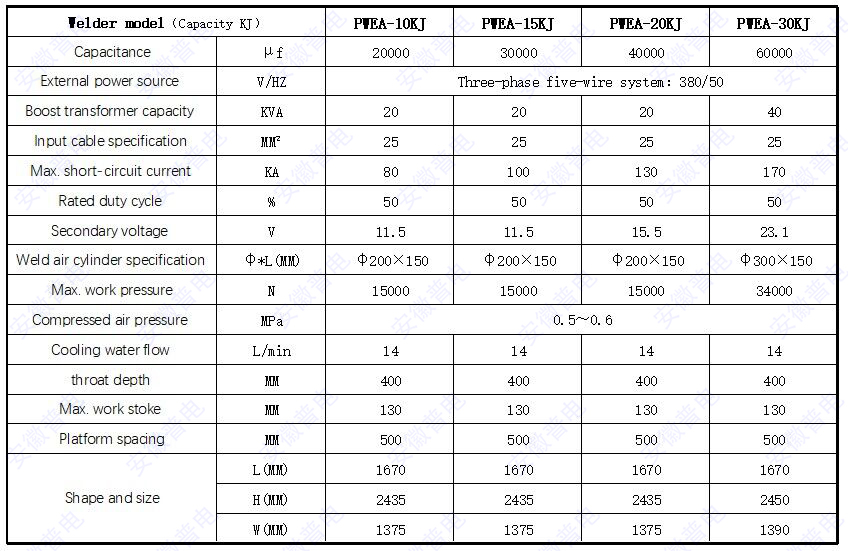

The requirements on power grid are low and do not affect power grid

Since principle of energy storage welding machine is to charge capacitor through a low-power transformer and then discharge workpiece through a high-power solder resistance transformer, it is not easily affected by fluctuations of power grid, and because the charging power is small, impact on power grid is much smaller than AC spot welding machine and DC spot welding machine with same welding capacity.

The discharge time is short and thermal effect is small

Because discharge time is less than 20ms, resistance heat generated by parts has not been conducted and diffused, welding process has been completed, and cooling has begun, so deformation and discoloration of welded parts can be minimized.

Welding energy stabilization

Since each charging voltage reaches set value, it will stop charging and turn into discharge welding, so welding energy fluctuation is minimal, ensuring the stability of welding quality.

Save energy

Because the discharge time is very short, long-term use will not produce overheating, discharge transformer and some secondary circuits of energy storage welding machine almost do not use water cooling.